Design Capabilities

Design Capabilities

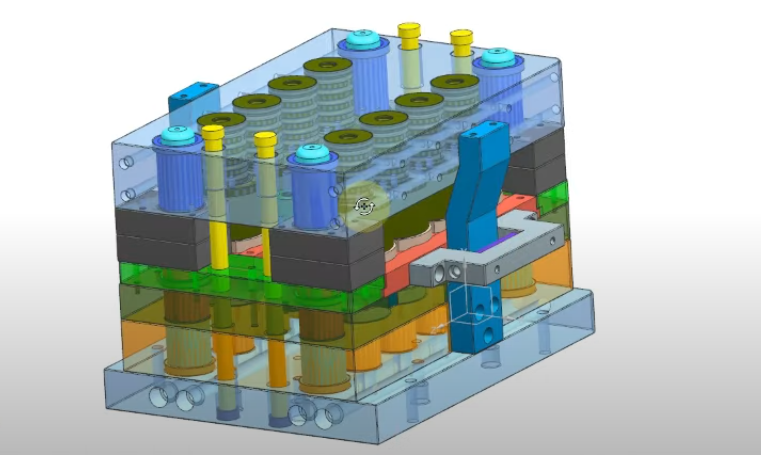

The in-house design studio at Ashoka Tools performs processes of Product design, mold analysis, mold design and mold process simulation thereby producing a finely engineered product for the end users.With the purpose of achieving best quality products, Acme uses advanced software for the process of product designing and molding. The company has setup a design studio equipped with advanced software. The high expertise levels enable Ashoka Tools to produce products with consistent dimensions

Ashoka Tools has installed latest software for carrying out quality driven Product designing, mold designing and molding process simulations. This advanced design method assures optimal thickness, thread fitment, stretch ability, weight, and other essential product features. Through this method, the company achieves optimum mold manufacturing processes, shorter mold delivery periods and lesser mold testing requirements. In order to ensure regular melt flow and pressure in all the cavities, the company has designed appropriate and balanced hot runners. Ashoka Tools ensures that each mold produced by the company carries essential characteristics such as efficient heat transfer and consistent cooling. This enables the company to achieve high preform quality with short cycle times.

Ashoka Tools also provides upgrades that help in improving output, reducing cycle times and adding functionality to the equipment. Efficient heat transfer and consistent cooling is ensured through technically embedded cooling channel structure &raging water flow..