Design & Engineering

Design Capabilities

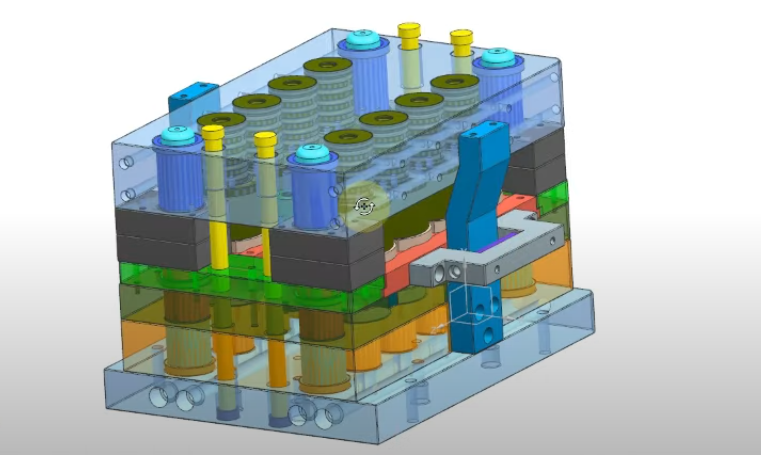

The in-house design studio at Ashoka Tools performs processes of Product design, mold analysis, mold design and mold process simulation thereby producing a finely engineered product for the end users.With the purpose of achieving best quality products, Acme uses advanced software for the process of product designing and molding. The company has setup a design studio equipped with advanced software. The high expertise levels enable Ashoka Tools to produce products with consistent dimensions.

Ashoka Tools also provides upgrades that help in improving output, reducing cycle times and adding functionality to the equipment. Efficient heat transfer and consistent cooling is ensured through technically embedded cooling channel structure &raging water flow.

Ashoka Tools has installed latest software for carrying out quality driven Product designing, mold designing and molding process simulations. This advanced design method assures optimal thickness, thread fitment, stretch ability, weight, and other essential product features. Through this method, the company achieves optimum mold manufacturing processes, shorter mold delivery periods and lesser mold testing requirements. In order to ensure regular melt flow and pressure in all the cavities, the company has designed appropriate and balanced hot runners. Ashoka Tools ensures that each mold produced by the company carries essential characteristics such as efficient heat transfer and consistent cooling. This enables the company to achieve high preform quality with short cycle times.

Research & Development

Ashoka Tools has an in-house R&D centre which is completely equipped with latest CAD/CAM/CAE workstations to provide the apex in their work. The Research & Development centre, at Acme, is fully equipped with advanced CAD/CAM/CAE workstations facilitating high end work process. The R&D centre is well developed and enables the company to produce superior designs of preforms, tailor-made to suit the requirements of the customers.

Ashoka Tools believes in achieving customer satisfaction at all times and its ability to transform complex requirements into comprehensive solutions helps it attain the same while keeping the quality levels high. Spearheaded by able engineers, Ashoka Tools succeeds because it focuses on progressive engineering and design expertise. The Design & Development studio at Ashoka Tools supports the R&D structure of the company and helps in converting the ideas into results.

Ashoka Tools themselves has an in-house R&D center.

Support

Ashoka Tools provides excellent after sale support to its customers. The support team is prompt in action and available to the customers 24*7 through multiple channels. Apart from online support system, a team offive qualified engineers is available round the clock toprovide technical support to the clients.

At any given point in time, the company maintainsinventory of spares available, which enables Ashoka Tools to deliver the parts with a quick turnaround time and serve the customers with effective after sales support. The downtime of the machine is therefore reduced to the barest minimum.